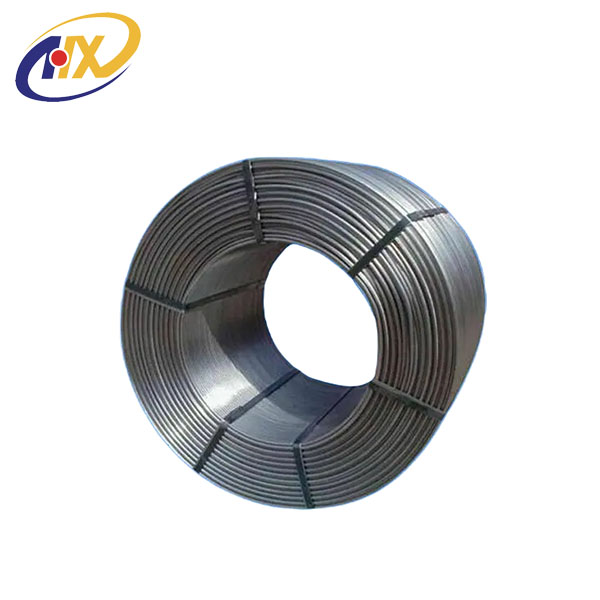

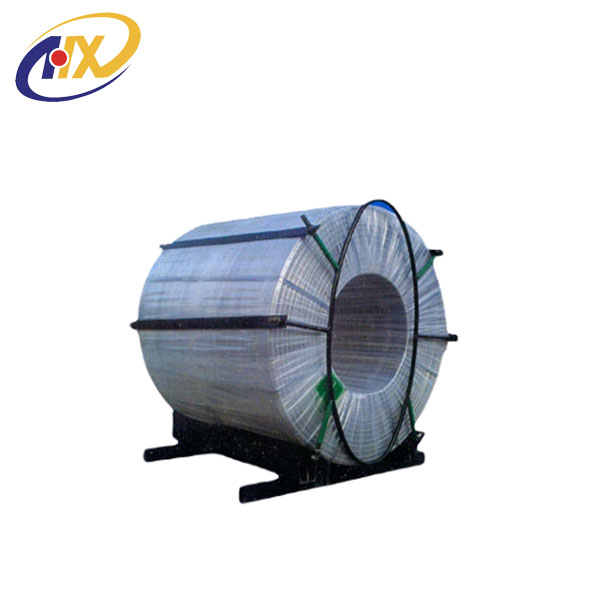

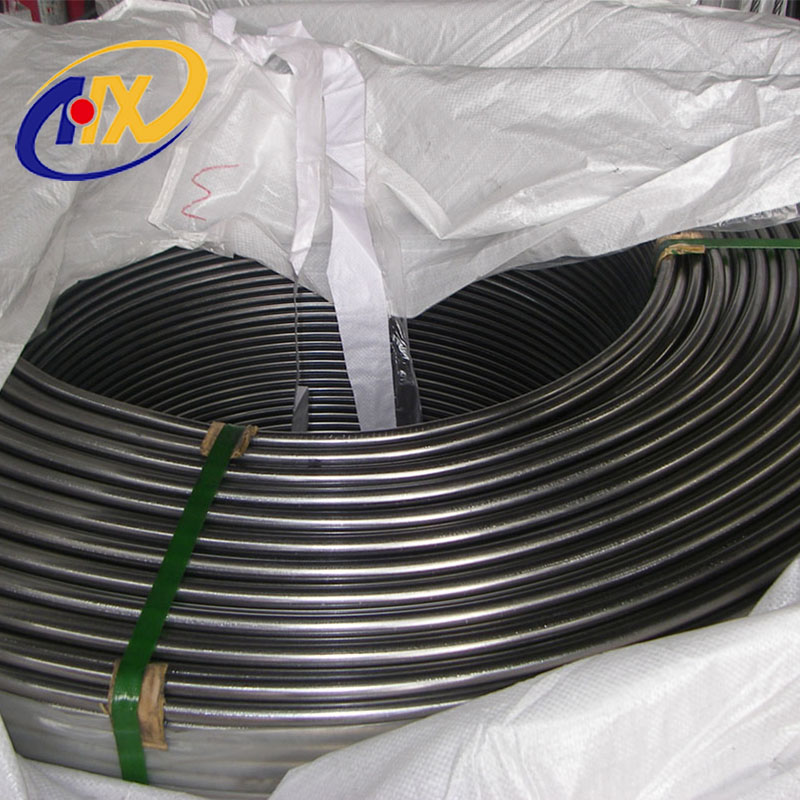

CaSi cored wire

casi-cored-wire technology is a new treatment in secondary steelmaking developed in recent years, alloy core wire can purify the molten steel, change the inclusion form, improve the cast ability of the importantly, it will increase the yield of alloy ,cut

We're here to help: Easy ways to get the answers you need.