Silicon carbon alloy application range

2022-06-08

Silicon carbon alloy product introduction

Silicon carbon alloy is a ferroalloy product for smelting silicon metal. It contains abundant silicon and carbon elements. Silicon carbon alloy is often used in casting and steelmaking, and it is also the most frequently purchased metallurgical material. Silicon carbon alloy for casting can improve cast iron. It can effectively improve the graphitization effect in the production of graphite cast iron, and is a good nodularizing agent and inoculant. Pressed, silicon-carbon alloy balls are by-products produced when metal silicon is smelted, and many steel manufacturers often purchase silicon-carbon alloy balls for use as a reserve army instead of ferrosilicon.

Silicon-carbon alloys are cost-effective, mainly because silicon-carbon alloys can be used instead of ferrosilicon. Silicon-carbon alloys are rich in silicon. Compared with ferrosilicon, silicon-carbon alloys have almost the same silicon content, but their ferrous alloys are expensive. However, it is much lower. Therefore, under the current situation of soaring ferrosilicon prices, many manufacturers have begun to purchase silicon carbon alloys as smelting materials, which can be used for deoxidation in the production of ordinary carbon steel to improve the purity and quality of molten steel. Iron is cheap, so in comparison, silicon-carbon alloys can better reduce smelting costs and effectively improve the efficiency of manufacturers. Therefore, silicon-carbon alloys are very popular with domestic manufacturers. Now more and more manufacturers begin to use silicon-carbon alloys as smelting materials, which are cost-effective. Favored by manufacturers!

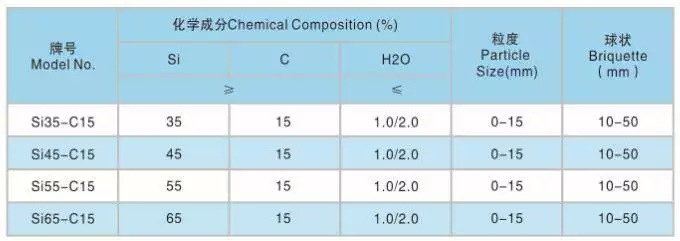

Chemical composition of silicon carbon alloy

Silicon carbon alloy application range

1. Silicon carbon alloy price is an ideal choice to replace ferrosilicon

Silicon carbon alloy is a high carbon ferroalloy product with carbon content between 15-30, but the silicon content can reach 65, 55, 45, 40 ferrosilicon product content, but the price is lower than that of ferrosilicon. The ideal substitute for ferrosilicon, the main reason for the low price of ferrosilicon is the reduction of material costs in its production. If only the silicon content is required to ignore the carbon content, silicon carbon alloy is undoubtedly an ideal choice to replace ferrosilicon!

2. Where is the high cost performance of silicon carbon alloy

When it comes to cost-effectiveness, it is a new popular word in modern society. It is just that more and more people are looking forward to it. In the metallurgical industry, silicon-carbon alloy is a product with high cost-effectiveness. Low-cost silicon-carbon alloy It is often very popular, so the cost-effectiveness of silicon-carbon alloys is being sought by more and more purchasing manufacturers.

3. Deoxidation of silicon carbon alloys

Silicon-carbon alloy contains silicon element. In the process of steelmaking, after adding an appropriate amount of silicon-carbon alloy, the silicon element in the silicon-carbon alloy reacts with oxygen, which reduces the oxygen in molten steel, thereby improving the hardness and quality of steel. , and the silicon element in the silicon carbon alloy has a good affinity with oxygen, so the molten steel also has the characteristics of no splash after being placed.

4. Slag Collection Properties of Silicon Carbon Alloys

Silicon carbon alloy also has the advantage of slag collection. Putting a certain proportion of silicon carbon alloy into molten steel can make the oxides in the steelmaking process quickly form agglomeration, which is convenient for filtration treatment, making molten steel more pure, and greatly improving the density and hardness of steel. .

Silicon carbon alloy can effectively increase furnace temperature

Silicon-carbon alloy is a temperature-resistant material. In the process of steelmaking, adding silicon-carbon alloy can increase the furnace temperature, increase the conversion rate of ferroalloy, and accelerate the reaction speed of molten steel and elements.

Silicon Carbon Alloy Packaging and Shipping

We have cooperative relations with a number of logistics centers, and use the way of automobile transportation supplemented by new ton belts + wooden frames for transportation to ensure that the goods are delivered to customers in a safe and fast way!

Introduction of silicon carbon alloy manufacturers

Hengxing Metallurgy is a manufacturer engaged in the production of silicon-carbon alloys. It has advanced imported silicon-carbon alloy production equipment and facilities, and is equipped with professional R&D personnel and CNC integrated laboratories. Every year, it attracts graduates from major universities for internship research. Since the establishment of the factory, it has always been responsible for the goal of adhering to the quality of each ton of silicon-carbon alloys. It has been well received by steel-making foundries of various sizes for a long time. In terms of silicon-carbon alloy prices, the company has always aimed to benefit customers so that more customers can benefit from Hengxing Metallurgy has a professional pre-sales and after-sales service system, which can guide the steelmaking and foundry to select the right silicon-carbon alloy products according to the process requirements, avoid waste, and truly achieve the purpose of saving costs. If you encounter any problems, you can consult and get professional solutions!

Real scene display of silicon carbon alloy manufacturers