The difference between ferrosilicon and ferro silicon granules

2023-05-04

Ferrosilicon is an ferro alloy composed of ferro and silicon. Ferrosilicon is an ferro silicon alloy made by smelting coke, steel shavings, quartz (or silica) as raw materials in an electric furnace;

The use of ferrosilicon:

1. Ferrosilicon is an essential deoxidizer in the steelmaking industry. In steelmaking, ferrosilicon is used for precipitation deoxidization and diffusion deoxidization.

2. Used as an inoculant and spheroidizer in the cast ferro industry. In the production of ductile iron, 75 silicon ferro is an important inoculant (helping to precipitate graphite) and spheroidizing agent.

3. Used as a reducing agent in ferroalloy production. Not only is the chemical affinity between silicon and oxygen high, but the carbon content of high silicon ferrosilicon is also very low. Therefore, high silicon ferrosilicon (or siliceous alloys) is a commonly used reducing agent in the production of low-carbon ferroalloys in the ferroalloy industry.

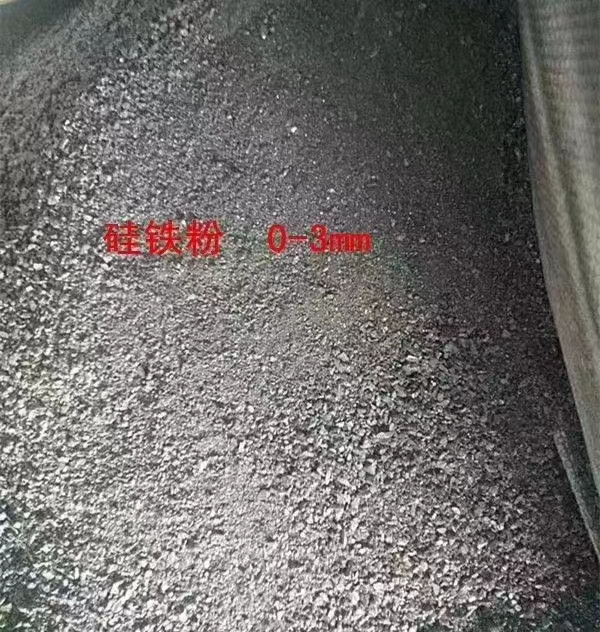

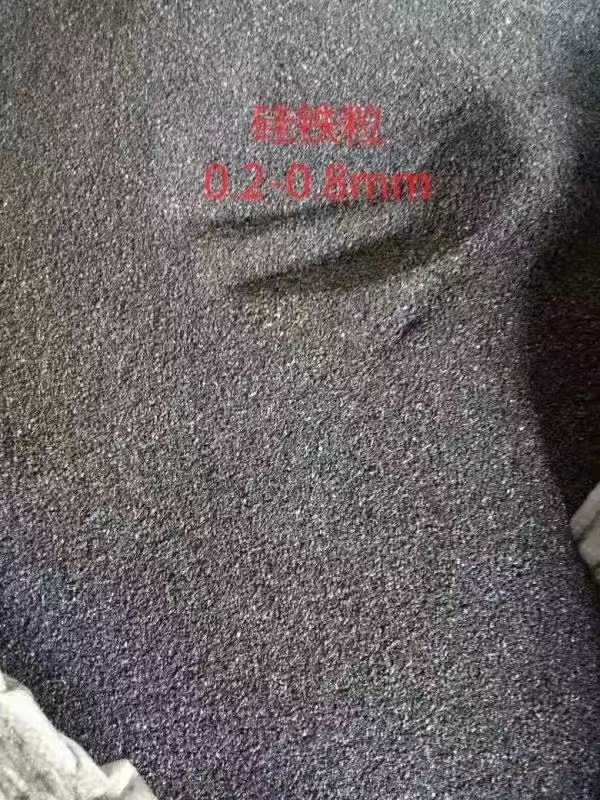

Silicon ferro granules are formed by crushing silicon ferro into small pieces in a certain proportion and filtering through a certain number of sieve leaks. Simply put,silicon ferro granules are small particles selected by crushing natural and standard blocks of silicon ferro according to different sizes. Currently, they are widely used as inoculants in casting factories on the market,

Silicon ferro granule supply size: 0.2-1mm, 1-3mm, 3-8mm, or customized according to customer requirements;

Advantages of Ferro Silicon Granule:

Silicon ferro granules can not only be used in the steelmaking industry but also as a commonly used metallurgical material in the cast ferro industry. This is mainly because silicon ferro granules can be used by cast ferro manufacturers to replace inoculants and spheroidizers. In the cast ferro industry, the price of silicon ferro granules is much lower than that of steel, and they are more easily melted, making them ferro alloy products with casting capabilities.

.jpg)

.jpg)

.jpg)