Silicon metal 553 production process

2025-05-16

Silicon metal, as an indispensable basic material in the modern industrial system, is widely used in non-ferrous metal alloy manufacturing, semiconductor production and other key areas.

Silicon metal 553 is an important grade that is commonly used in the market due to its excellent performance and wide applicability. How is silicon metal 553 produced? What are the key aspects of the production process? Next, we will discuss in depth.

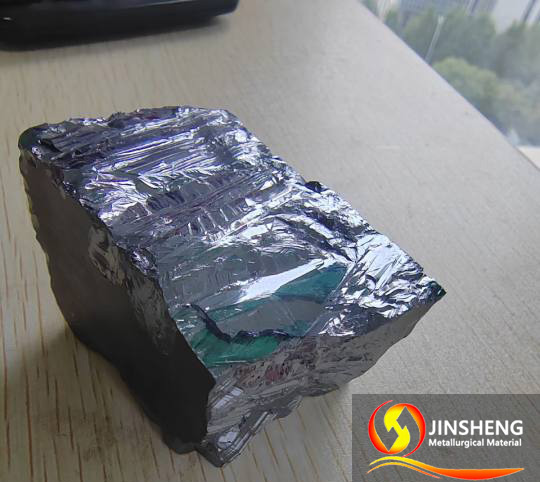

Silicon Metal 553

Definition and Classification

Silicon metal, also known as crystalline silicon or industrial silicon, is a gray semiconductor material with a metallic luster. In industrial production, it is mainly melted through electric furnaces, using quartz and coke, and is often used as an important additive in non-ferrous metal alloys.

Silicon metal is classified mainly on the basis of the content of three main impurities: iron, aluminum and calcium. Under this classification system, different grades such as 553, 441 and 3303 have been developed, and silicon metal 553 occupies a key position in many industrial applications.

Specifications and Properties

Silicon metal 553 has strict compositional criteria: Silicon content of 98.5% and above, and iron, aluminum, and calcium contents of no more than 0.5%, 0.5%, and 0.3%, respectively. This compositional ratio gives silicon metal 553 its unique physico-chemical properties, which stabilize it in different industrial scenarios.

Advantages and applications

Silicon metal 553 offers the significant advantages of versatility and cost-effectiveness. In the field of aluminum alloy production, it is the key to improving alloy quality. With the addition of Silicon Metal 553, the strength of aluminum alloys is enhanced, oxidation and corrosion resistance are significantly improved, and casting performance is optimized.

In addition, Si553 is widely used in refractory and powder metallurgy industries as an excellent antioxidant to enhance the products' high temperature resistance, wear resistance and oxidation resistance.

Silicon metal 553 production raw materials

Raw materials: silica

Silica is the core raw material for the production of silicon metal 553, industrial production requires the fine material into the furnace, the composition of silica has strict regulations: SiO₂ content of 99% and above, Fe₂O₃ ≤ 0.15%, Al₂O₃ <0.2%, CaO <0.1%, and the total sum of the impurities preferably controlled within 0.6%.

In addition, silica usually exists in the form of quartz or pebbles, must have good thermal resistance, not easy to crack when subjected to thermal phase change in the furnace, can withstand higher temperatures without being destroyed.

Auxiliary materials: carbonaceous reductants

In practice, in order to ensure the quality of the product, the carbonaceous reductant has strict requirements.

The ideal carbonaceous reductant needs to have high fixed carbon, low ash, moderate volatile matter, low moisture, high resistivity, reactivity, and a certain mechanical strength and other characteristics. Only such a reductant can give full play to its role in the smelting process.

Production process of metal silicon

Raw material treatment

First of all, the silica and carbonaceous reductant need to be cleaned to remove impurities attached to the surface; secondly, through screening to ensure that the raw material particle size in line with the production requirements; finally, drying treatment to reduce the moisture content of raw materials.

This series of operations can effectively ensure the purity and quality of raw materials, laying a solid foundation for subsequent production.

Smelting process

The treated silica and carbonaceous reductant are fully mixed according to a specific ratio, and then sent to the submerged arc furnace for smelting. In the high temperature environment (usually need to reach more than 1800 ℃), silica reduction reaction, and gradually converted into silicon metal.

Submerged arc furnace plays a key role in the melting process, its stable high-temperature environment and precise automatic control to ensure that the reaction is fully carried out to ensure product quality and production efficiency.

Product Processing

After the melting is completed, the silicon metal in the high-temperature molten state needs to be cooled and molded, so that it solidifies into a solid state. Subsequently, crushing is carried out to process the silicon metal into the appropriate particle size. Finally, it is packaged and stored to facilitate the transportation and use of the product.

It is worth mentioning that after the gas generated in the melting process is dusted, the silicon powder can be recycled and reused, which not only realizes the effective use of resources but also reduces environmental pollution.

The application of silicon metal

Silicon metal has a wide range of applications.

Aluminum alloy products. It can strengthen the comprehensive performance of the alloy and improve product quality.

Cold-rolled silicon steel products. The addition of silicon metal can improve the magnetic properties of steel and enhance its value.

High-purity semiconductor products. With the continuous progress of technology, integrated circuits and large-scale integrated circuits made of silicon semiconductors are increasingly widely used in various fields, and the market demand continues to grow.

Silicone products, silicone, silicone resin, and silicone oil. Silicone can maintain flexibility in the temperature range of -70℃ to 200℃, and is commonly used in the production of high-temperature gaskets and cold insulating materials; silicone resin can be used to produce insulating paints and high-temperature coatings; silicone oil can be used in the production of high-level lubricants, polishes and so on.

Heat-resistant material. Silicon metal is used in the production of materials such as Si3N4, which can effectively improve the heat resistance, wear resistance and corrosion resistance of the material.

Conclusion

The production of silicon metal 553 is a systematic and rigorous process, from the strict screening of raw materials, to the precise control of each link in the production process, to the fine processing of the product, each step has an important impact on the quality of the final product.

If you have further requirements for customized service and market quotation of Silicon Metal 553, please feel free to contact us.